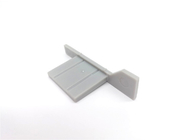

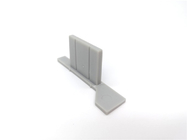

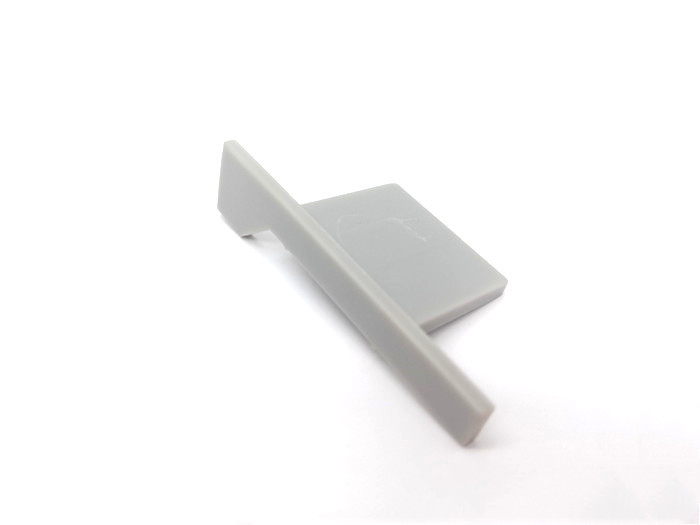

PA66 Material NAK80 DME HASCO Custom Car Molding

Product Details Description

| Product Description |

Plastic injection mold |

| Plastic Materials |

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard |

DME/HASCO standard |

| Other materials |

Rubber, Slilconce rubber |

| Quality |

RoSH and SGS standard |

| Feature |

Non marking and Non flash |

| Package |

Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time |

T1, 4-5 weeks after the mold 3D approved |

| Mould Base |

Hasco Standard, European Standard, World Standard |

| Mould Base Material |

LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish |

Texture(MT standard), High gloss polishing |

| Cavity/Core Steel |

P20, 2311, H13, 2344, Starvax 420, 236,S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Cavity number |

Single/multi cavity |

| Hot/ Cold Runner |

HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip,...etc. |

| Mould Life |

300,000 to 1,000,000 Shots. (According to your requirement.) |

| Design & Program Softwares |

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

| Equipments |

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-1300T available. |

Quality Assurance is the key to success for KYE Moulds, high-quality/defect free products is the reason KYE enjoys repeat business from our list of satisfied customers.We use high precision measurement tools and advanced video devices to check all parts and processes from incoming material till outgoing final inspection, to ensure only qualified products will be sent out to our customers.

Our Advantage

1. Thorough project management system

KYE has thorough project management system from sales team to engineer and worker team.

2. Professional Engineer team

KYE has 6-8 engineers with 10~15 years of full expereience, their professional skill can offer you the best solution for the project and help you manage the project in the best effective way.

3. Owned mold making workshop

KYE has owned mold workshop with 2000 squre meteres in house to make sure the high quality and lead time.

4. Injection molding workshop

KYE has around 40-50 sets of injection machine range from 50T to 600T.

5. Various Service

We offer various service including Automotive parts, Home Appliance, Electronic and Medical parts with one stop service

including product design, mould fabrication and second processing,such as Spray painting,Printing, Chrome, Engrave and assembling,etc.

What KYE can offer

1. Mold Building

Complex Surfaces

Hot-Runner Capability

Assembly Fixtures

Mold up range from samll, middle and large

2. Engineering/ Technical

Mold flow analysis

Mold design

Supplier Managed Inventory

Project management

Design for Manufacturing

3. Technical Injection Molding

High Pressure Thin wall

Small Precision and Large Cosmetic

Structural Foam

Robotic and Automated Pick and Place

4. Plasting/die-casting molding

FAQ

Q: What are the advantages to having my parts manufactured locally?

A: Longeron can offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand.

Q: I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: My components have already been developed on CAD. Can you use the drawings?

A: Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q. What's your mold tolerance?

A. 0.005-0.02mm according to different product requirements.

Q. What I should offer to you if I need a quote?

A. 2D product drawing & 3D File, or send us real plastic sample.

Q. Which material will your factory use to make a mold?

A. Our regular material has NAK80, S136, LKM, DAIDO, HASCO, DME

Q. What's your delivery time for molds and plastic injection products?

A. Our delivery time for mold: 3-5 weeks as mold structure complexity.

Plastic injection products: 3-18 days.

Q. What we need to provide if we want to start cooperation?

A. 1. 3D file or Real sample for your products;

2. Material you require;

3. Surface treatment requirement

KYE always keep perfect quality,best service and customer-first as our company-running theory as a result of winning big international market covering USA,Germany,UK,Italy,Australia,Middle-east ,South–east Asia and North Africa etc.thanks for your visit and looking for the inquiry from you!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!