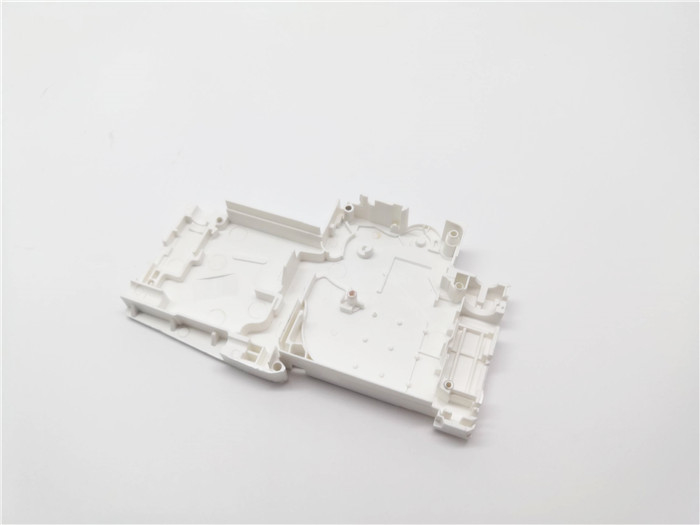

Polishing Plastic S136 Precision Injection Moulding Service

Mold Details Description

| Mold Details |

Type |

Prototype mold and exported / production mold |

| Standard |

Hasco,DME,LKM,FUTABA,other |

| Cavity/Core material |

AB Plate 1.2343 / 1.2311/SKD61,S136,NAK80,H13,738H,other |

| Injection |

Cold runner/hot runner(Moldmaster,YUDO,INCOE,HUSKY,MOLD-TIP,other) |

| Mold life |

1,000pcs, 300,000, 500,000-1,000,000 shots |

| Service |

One stop service |

Design- Mockup- Manufacturing- Assembly |

| Design |

CAD/CAM technical platform and perfect engineering data switching system which enable us to have elastic choices to offer service to our customers.

UG 4.0

DXF, DWF, PRT, SAT, IGES or STE format for mold design and layout

|

| Mockup |

Rapid laser mockup /CNC mockup process |

| Manufacturing |

Prototype mold,production mold,plastic parts production |

| QC |

Latest precise detecting instruments

Well trained and skillful inspectors

Timely feedback to manufacturing department

High yield rate and timely delivery

|

| Delivery |

SAMPLES SHIPPED BY FEDEX,DHL,TNT,UPS.

Sea or air shipment for Mold/mass production

|

Our Service

1. New project/design development assistance, base on customer’s samples or design drawing;

2. When the customer encounter bottleneck, give them some technical assistance;

3. Help the customer complete the 3D design drawing;

4. Simulate the effect of the product by simulation software and offer the simulation report;

5. Test Mold: Test Mold and Sample Making;

6. Delivery Mold: Delivery to Customer;

7. Product Making;

8. After service: After Sale Information Communication.

OUR ADVANTAGE

1. Owned mold making workshop

KYE has owned mold workshop with 2,000 squre meteres in house to make sure the high quality and lead time.

2. Professional Engineer team

11 year of full expereience in line of plastic mold and molding, their professional skill can offer you the best solution for the project and help you manage the project in the best effective way.

3. Various Service

Our service including Automotive parts, Home Appliance, Electronic and Medical parts with one stop service

including product design, mould fabrication and second processing,such as Spray painting,Printing, Chrome, Engrave and assembling,etc.

4. Injection molding workshop

KYE has around 40-50 sets of injection machine.

5. Thorough project management system

KYE has thorough project management system from sales team to engineer and worker team.

FAQ

Q: What’s the advantages of your company?

A: we have more than 10 years experience mold design team, skillfull worker and sales team and all inhose mold making.

Q: What should we do if we receive defective products?

A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP.

Q: How to pack the moulds and products?

A:1).For moulds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mould, finally pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!