|

1 2 3 4 5 6 7

Drilling Machine

mold workshop 2

polishing department

Drilling Machine

Tooling workshop

EDM Machine

Mold workshop 1

|

Drilling Machine |

mold workshop 2 |

polishing department |

Drilling Machine |

Tooling workshop |

EDM Machine |

Mold workshop 1 |

|

1 2 3 4 5

|

|

|

|

|

|

|

1 2 3 4 5

|

|

|

|

|

|

One-stop service

We are an innovative and dynamic team, who has capacity to handle the whole project from design,mold fabrication and second-processing including spray painting,printing,chrome,engrave,assembling,packaging etc and shipment issue.We are not only handle plastic mold fabrication, but make die-casting mold and molding, even components machining,.

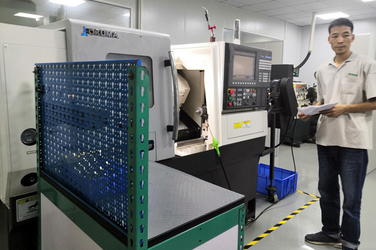

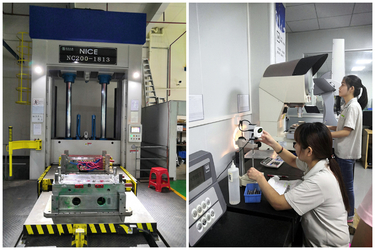

Advanced facilities and skillful staffs

In order to ensure the quality and meet the customer`s requirement, we own various advanced facilities in house, most of which are imported from Japan, Germany and Taiwan.

We have sensitive sales team, who always can give rapid respinse to the market demands and fluctuations on time. Our sales team is not only have sense of service for market, but also cultivated with technical knowledge regularly. In this way, the sales team know how to manage the whole project and offer the most effective process for the customers.

In order to keep all of our staffs to be stable and well-educated, we devote a lot on staff training, especially for the engineers and technicians. Therefore, all of them are always proficient in operating the updated machines and know how to save the time and cost.

Effective organization

KYE always keep perfect quality,best service and customer-first as our company-running theory as a result of winning big international market covering USA,Germany,UK,Italy,Australia,Middle-east ,South–east Asia and North Africa etc.We have advanced detection equipment and scientific management system from administration, produce and quality controlling, which ensure the effective organization for whole factory.

![]()

KYE team always keep growth with the demands of the customer and market. We not only upgrade our technology, facility, but also improve our team with regular tranining. Meanwhile, the enpargement of the production line and workshop also help to improve our capacity.

Our skillful staff work with advanced qquipements with stable technique to meet the high quality requirement of customer. We not only can help customer deal with the design by OEM 3D drawing, but also have capacity to handle the scaning actual sample to acheive part 3D and improve further design based on customer`s requirement. Thereby, we have professional team to catch up customer`s idea and realize the design to mold fabrication and molding with one stop solution.

Our experienced engineer and QC engineer work together with workers on the production line to make the technology section and solve the problems whle production. We implement the ISO9001:2000 quality controlling system in the production.Quality is the life is we continue to improve product quality, the driving force for the pursuitof perfect quality, evey KYE people knows they are responsible to the quality and the customer.

We are proud of that we always offer the customers mold and product with good quality, lead time and effective response. KYE will continue to keep it in mind to serve our customers.The company insists that quality is life, innovation is power, reputation is the future!

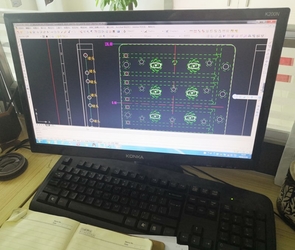

KYE has a team of professional engineer for the product design with full design experience and skill.The desgined products have received big favor from our customers. The service includes Product design, mold-flow analysis and prototyping.

1.Product design

a. We can develop new products based on samples or prototypes by using reverse engineering,3D digitizing and laser scanning technology.

b. We can develop new products according to simple sketch and brief description like function.dimension etc.We provide customers with 3D model and 2D as request.

c. We can join in the customer’s design group. for example: summit the economic plan to save cost.point out the existing design problems for product such as the undercut.sharp angle .processing difficulty and so on.

![]()

2.Mold-flow analysis

This is a very important process,because we need to understand the possibility of product in advance in order to prevent some possible problems like air trap.mark.and welding line etc. especially for the big product,so we introduce the advanced moldflow analysis software and professional engineers to stimulate ,analyze ,optimize and validate plastic parts and mold design .it effectively pre-prvent the potential problems as so to save cost ,control quality and guarantee delivery time.

![]()

3.prototype-making

For some projects,Prototype is inenvitable process.it can help engineer check the product function and also prevent some problems which should be found after mould trial. In order to meet the requirement,we bought the advanced prototype equipment and cultivate the high-skill staff to do the prototype by CNC or laser machine . As a result ,it can help us provide customers with high-quality prototype for confirmation very fast.

4.Injection

It is ok to handle the injection from 80 tons up to 1600 tons:

Horinzonal injection machine

vertical injection machine

Double colour rotary machine

with air and robot assist injection machine

5.second –Processing

Spray painting

Pad printing and silkscreen printing

Engraving

Assembling

Contact Person: Mr. jeff

Tel: 0086 139 2681 9972

Fax: 86-769-8162-3892

DME Standard S50C LKM 718H Custom Injection Mold Maker

V0 PC Fire Protection Cold Runner OEM DMEElectronic injection Mould

500000 Shots 65A TPE Resin DME HASCO Insert Mould