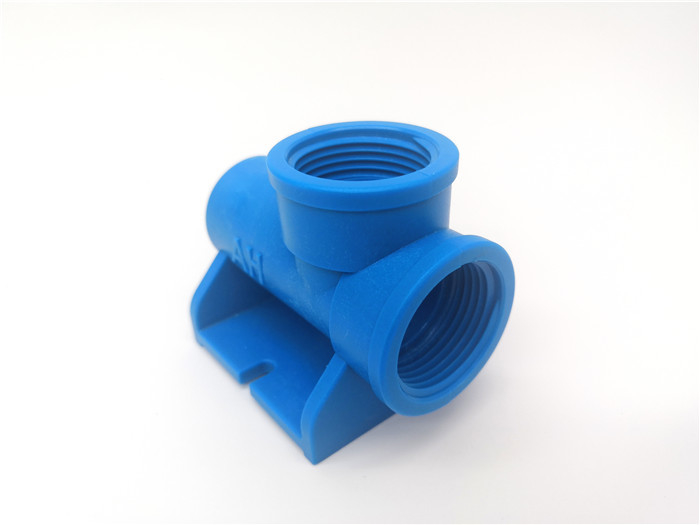

Hydraulic Engineering Edge Gate NAK80 LKM Precision Molds

Product description

| Mould standard |

LKM |

| Mould type |

2 plate-mould |

| Mould base steel |

S50C LKM, DME, LKM & HASCO & DME, HASCO, LKM Mould Base |

| A/B plate steel |

P20 |

| Core/Caviry steel |

P20/718/738/NAK80/S136, NAK80, S136, P20, 718H |

| Runner type |

Cold runner |

| Gate type |

Edge-gate |

| Cycle time |

25 S |

| Design software |

CAD, UG, Proe |

| MOQ |

1 set |

| Payment term |

T/T |

| Package |

Artificial Wooden Box with Steel Frame |

| Deliverly date |

4-5 Weeks |

| Mould number |

According to customer requirement |

| Mould life |

500,000 shots shots |

KYE is a professional plastic injection molding company since 2009. We provide high-quality, low-cost plastic injection mold tooling and custom plastic molded parts to customers all over the world. We provide custom plastic injection molding and parts at a very competitive cost and scientific project management:

1. Customized Making

- Per your drawings or samples, we can customize your mold.

- Per your requirement, we can modify and design your parts structure to establish the overall 3D effect drawing. And per above 3D drawing, we can provide mold making quotation and product molding quotation to you to help you to do the entire costing analysis.

2. Prototype Making

- in initial stage, after confirming the product design, size, material, and price…etc, if you need, before starting to make the real mold, we can make the prototype for you to help you understanding the product detail and its outlooking (Ps. we will estimate the prototype cost report to you from 3D printing or from NC milling way).

3. Purchase Contract Making

If both of us agree to sign the contract, we will mention the working detail, lead time, inspection standard, payment term information…etc on the contract.

4. During the mold manufacturing period

- We will send the update working progress report in every 1-2 week with photos.

- Before commencing making the mold and the machining process, if customer needs to adjust the product’s shape slightly, we will not charge the extra cost.

- If the machining process is on-going, and customer needs to adjust the product design, we will study and give our report to see whether we should charge extra cost or not.

- We will send T1, T2 or T3 samples till meeting customer’s satisfaction.

5. If customer places the product production orders to us

- After the final trial samples is approval by customer, if customer places the product production to us, we will be responsible for the mold maintenance and performance for all.

6. Packing information

- For mold, we pack with standard exported wooden box with fumigation process.

- For product, if there is no specific packing requirement, we will use regular carton box and bag (free of charge). If customer requires specific packing way,

We can help customer to do the assembly, packing and the printing from case to case.

7. Transportation

- Customers can use their own forwarder or we can help customer to arrange any sea or air transportation forwarder to deliver the goods to customer’s address.

FAQ

1.Q: Are your a factory or a trading company?

A: We are a factory located in Chang`an, Dong Guan ,Guang Dong, China.

Customized mould base

Q1: Does your company make mold by yourself?

A: Yes, we have our owned mold workshop around 2000 square meters including mold and molding.

Q2: What is the software you use for design and mold making?

A: We usually use UG, PROE, CAD, CAD/ProE/UG/SOLIDWORKS for mold 2D and 3D design.

Q3: Will offer the free sample?

A: We offer 10-20pcs free sample for each mold trial and the customer could in charge of sample delivery cost.

Q4: What is your payment term and how do you pack the mold for delivery?

A: Usually, our payment term is 50% on PO, 30% on T1 sample and 20% on mold approval before delivery by T/T.

If it is the molding part, the payment term is 50% upon PO and 50% afte inspection before delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!