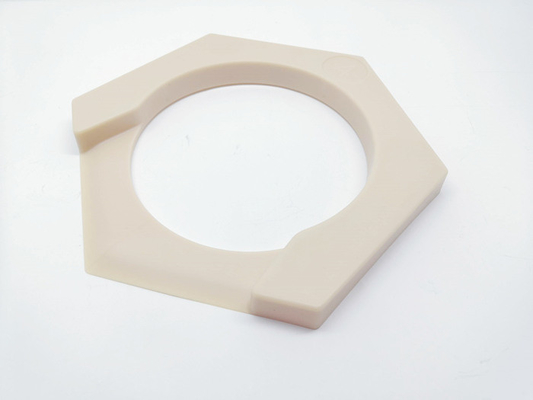

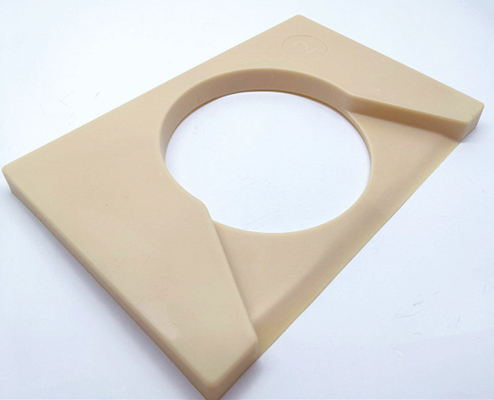

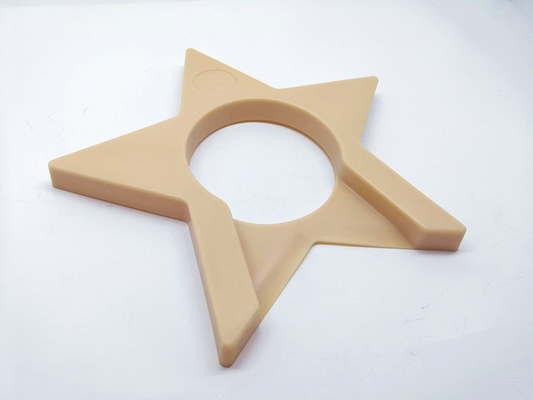

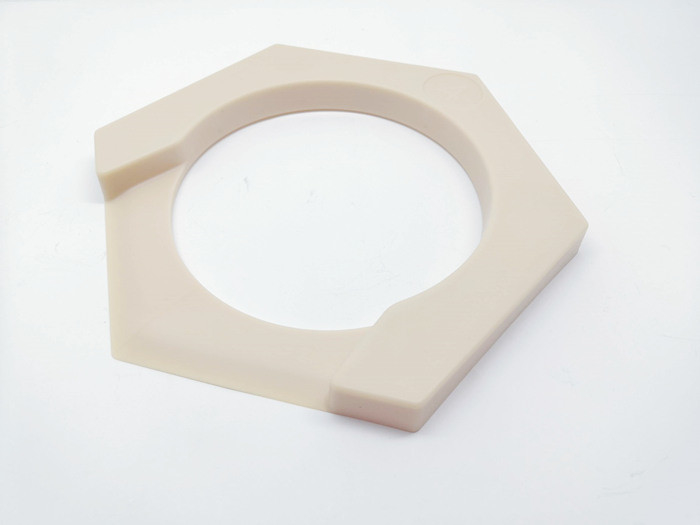

PP Resin 718H 500000 Shots Home Appliance Injection Mold

Mold details description:

| Mould standard |

DME |

| Mould type |

2 plate-mould |

| Mould base steel |

S50C LKM, DME, LKM & HASCO & DME, HASCO, LKM Mould Base |

| A/B plate steel |

P20 |

| Core/Caviry steel |

NAK80/S136, NAK80, S136, 718H |

| Cycle time |

45s |

| Gate type |

Fan gate |

| Runner type |

Cold runner |

| Design software |

CAD, UG, Proe |

| MOQ |

1 set |

| Mould life |

0.5 million shots |

| Package |

Artificial wooden box |

| Deliverly date |

4-5 Weeks |

| Payment term |

T/T |

KYE Mould Technology Limited is set up at 2009, located in the well-known industrial town Chang`An,Dongguan city of China with convenient transportation and booming economy.Our service covering industrial of Automotive, Electronic, Medical, Precision product,home appliance, over-moulding, Die-casting mold design, and Rubber product etc. range small, middle and large size.

Manufacture Capabilities

1. New project/design development assistance, base on customer’s samples or design drawing;

2. Help the customer complete the 3D design drawing;

3. When the customer encounter bottleneck, give them some technical assistance;

4. Simulate the effect of the product by simulation software and offer the simulation report;

5. Test Mold: Test Mold and Sample Making;

6. Delivery Mold: Delivery to Customer;

7. Product Making;

8. After Sale Information Communication.

Brief introduction of service cooperation process

1. Customized Making

Per your drawings or samples, we can customize your mold.

Per your requirement, we can modify and design your parts structure to establish the overall 3D effect drawing.

2. Mold development and processing

After the customer's rapid prototype or diagram file is confirmed, we enter the mold design and processing flow.

2. Mould test review

After trial of mold, according to mold test situation and test report and testing sample,we will discuss with customers to further verify product quality and requirements, and confirm samples.

3. Modification and improvement of the mold

According to the review report, improve the modification of the nuances of the mold. And re-testing and back-surface processing, etc., to achieve customer required quality and confirmation.

4. Injection Molding Processing

The company has a first-class injection molding machine, check the quality of the mold and adjust the appropriate process parameters, complete the product injection molding, inspection packaging. After removing the nozzle, the quality of the injection parts will be checked, the qualified semi-finished products will be packed, ready to transfer to the next process, and the unqualified products should be collected and recycled.

5. Surface treatment

6. Complete assembly

7. Delivery to customers.

FAQ

Q: How soon can i get reply after sending inquiry?

A: All inquiries would be replied within 24 hours, except sleeping time in China; and our cell phones are standing by any calls at any time.

Q: What should I provide for price enquiry?

A: The 3d drawing (in STP/ STEP/ IGS/ X_T/ SLD format) with information about material, quantity, surface treatment, tolerance, and requires.

Q: If I don't have drawing, how can I get prototype?

A: If you don't have any drawing, you can send us your samples, we'll scan it and make the drawing first, then make prototype for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!