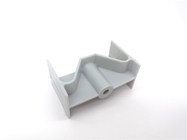

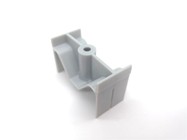

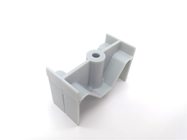

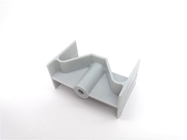

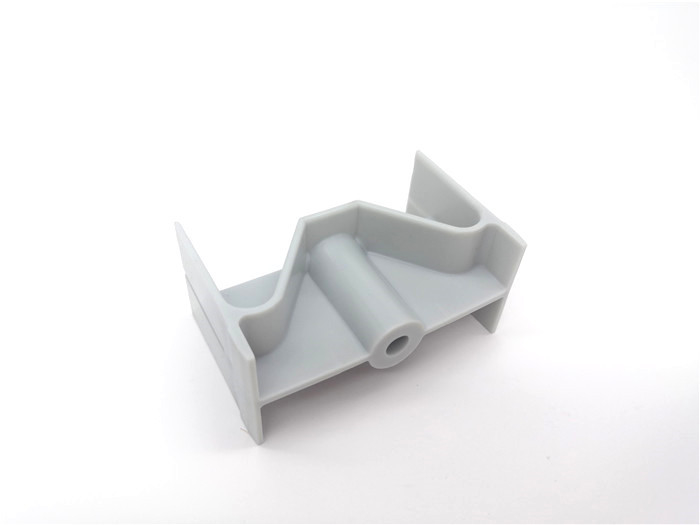

Cold Runner PP Plastic DME HASCO Custom Plastic Moulding

Product Details Description

| Description |

Plastic injection mould |

| Mould Base |

Hasco Standard, European Standard, World Standard |

| Mould Base Material |

LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish |

Texture(MT standard), High gloss polishing |

| Cavity/Core Material |

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner |

HUSKY, INCOE, YDDO, HASCO, DME, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life |

5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Software |

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

| Equipments |

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T

available. |

Being in line of plastic injection mold and molding, KYE count with an innovative and dynamic team, with more than 10 years of experience.We count with an innovative and dynamic team, with more than 10-15 years of experience of mold manufacturing:

Sales Team

In order to kee all sales to offer good service for all customer, we devote a lot into the training both on technology and project management. All sales not only can communicate with cusomter smoothly by mail,skyep, wechat and phone, but also deal with the project management from DFM report, mold process following up, mold trial and delivery.

Engineer and technical team

All staffs with 10-15 years expereicen of plastic injection mold design, manufacture and project management. Our team can handle mold design, prototype-making,Mold-flow analysis, injection mold and die-casting mold manufacture, plastic part and die-casting parts molding.

Quality team

We have high precision measurement tools and advanced video devices to check all parts and processes from incoming material till outgoing final inspection, to ensure only qualified products will be sent out to our customers.

KYE team always keep mind that "Quality first,on time Delivery, Perfect after service" and implement of “design for manufacture” solution ,as a result, we save money& time and offer competitive product cost for all customs.

What KYE can offer

1. Engineering/ Technical

Mold design

Mold flow analysis

Project management

Supplier Managed Inventory

Design for Manufacturing

2. Mold Building

Mold up range from samll, middle and large

Complex Surfaces

Assembly Fixtures

Hot-Runner Capability

3. Technical Injection Molding

Structural Foam

Small Precision and Large Cosmetic

High Pressure Thin wall

Robotic and Automated Pick and Place

4. Plasting/die-casting molding

FAQ

1. What is the normal process of a new project

It usually begins with a drawing/sketch or a similar samples. We then collect the data required for project quote and any special material requirements if you may have, after study of your material & through our interview process. Once we have all of the information we need, we will complete your quote. If the project is approved, we ask for 50% deposit to cover material costs, and the manufacture begins, then 30% at T1 mold trial and 20% before mold approval and delivery.

2.What material should I use

There are almost 100,000 materials in the marketplace today, so it can be very overwhelming, but if we can learn about your application, for instance, will the part be outside? What kind of abuse will it need to withstand? We can often recommend grades that are readily available, and less expensive.

3. Which format you prefer for drawings file to send inquiry

You may send us product drawings / parts drawing in .IGES ,STEP or X_T, which is preferred format

4. What is involved in injection mold preventive maintenance

All molds have moving pins in them to eject the part out. Maintenance will include periodic greasing of these pins, as well as all other moving components, and cleaning of the cavity and core surfaces. Best of all, we provide lifetime maintenance at no additional cost on all of our customer molds!

5. How will you control the quality

We have quality control department, which will set up control plan before stating the project.

6. I have no 3D drawing or 2D drawing , how should I start the project

You can supply us a sample, we will help to finish the 3D drawing design.

7. What is the packing facility for export

We are packing the moulds/ products that is easy broken in wooden box, with fumigation of full box and taking certificate from authorized agency. and we can pack the cargos as customized.

8. How long does it take to build an injection/blowing/silicone /die casting mold

Depending on the products' complexity and structure, it can range from 2 to 12 weeks.

9. how soon can i get a quotation

Normally, we can get back you within 24 hours when getting your detailed 3d drawing and requirements. if projects include many different parts, we will try our best to get back asap. and we hope the inquiry you send us is with details so that both of us can save the time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!