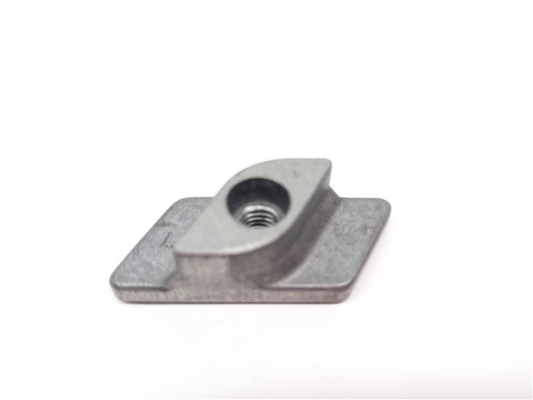

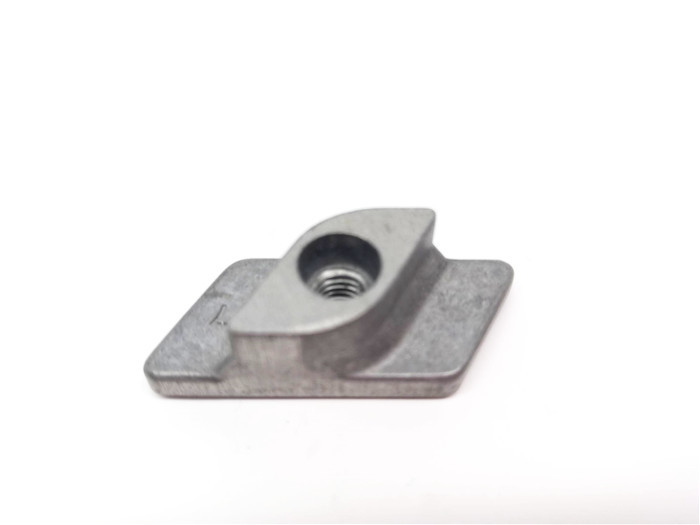

A356 Furniture Fittings DME 738H Die Casting Mould

KYE team is at your service offering professional expertise, flexibility and accuracy in assumed deadlines.We are able to offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement

Being in line of plastic injection mold and molding, we count with an innovative and dynamic team, with more than 10 years of experience.We count with an innovative and dynamic team, with more than 10 years of experience of mold manufacturing.

Sales Team

in order to kee all sales to offer good service for all customer, we devote a lot into the training both on technology and project management. All sales not only can communicate with cusomter smoothly by mail,skyep, wechat and phone, but also deal with the project management from DFM report, mold process following up, mold trial and delivery.

Engineer and technical team

all staffs with more than10 years expereicen of plastic injection mold design, manufacture and project management. Our team can handle mold design, prototype-making,Mold-flow analysis, injection mold and die-casting mold manufacture, plastic part and die-casting parts molding.

Quality team

we have high precision measurement tools and advanced video devices to check all parts and processes from incoming material till outgoing final inspection, to ensure only qualified products will be sent out to our customers.

KYE team always keep mind that "Quality first,on time Delivery, Perfect after service" and implement of “design for manufacture” solution ,as a result, we save money& time and offer competitive product cost for all customs.

Product Details Description:

|

| Mould standard |

DME/HASCO standard |

| Mould type |

2 plate-mould |

| Mould base steel |

S50C LKM, DME, LKM & HASCO & DME, HASCO, LKM Mould Base |

| Core/Caviry steel |

P20, 2311, H13, 2344, Starvax 420, 236,AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Runner type |

Cold/HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip,etc |

| Gate type |

Edge-gate |

| Finishing |

High Gloss, Fine Grain, Electroplating, Painting, Printing, Texture etc. |

| Mold life |

1,000 to 1,000,000 shots(according to your requirement) |

| Design software |

CAD, UG, Proe |

| MOQ |

1 set |

| Payment term |

T/T |

| Package |

Artificial Wooden Box with Steel Frame |

| Deliverly date |

4-5 Weeks |

| Mould number |

According to customer requirement |

|

OUR ADVANTAGE

Quickly reply

Our sales team can reply you on time, usually we feedback less than 12 hours, and offer the quotation less than 24 hours with simple product, complex products usually less than 48 hours.

Professional solution service

Base on your quantity requst, our engineer can give you the professional advise, for example if new product for testing the market, so we usually advise you to select the short mold life with cheap cost. But big batch product molds, our engineer will advise you to use hard steel for long mold life.

Complex product

Our engineer can do the 2K molds, gear molds, over molding molds, unthreading molds, many slide undercut undercuts molds, pline moving sliders molds etc, they are famillar with the Hasco, DME, LKM etc export molds standard, and also famillar with the hot runner, INCOE, YUDO, MOLD master etc.

Quality control

Our engineer can control the product quality with their professional technology, they check the molds one step by one step before shipping to keep the molds can be running smoothly after shipping to the customer facotry, they also check the product quality with professional experience also with many QC form to work.

Project process

| Quote |

According to sample, drawing and specific requirement. |

| Discussion |

Mold material, price, payment, etc. |

| Advance |

Payment by proforma invoice. |

| Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| Mold Tooling |

We start to make mold after mold design confirmed. |

| Mold Processing |

Send report to customer once each week. |

| Mold Testing |

Send trial samples to customer for confirmation. |

| Mold Modification |

According to customer’s feedback. |

| Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

FQA

Q: Are you trading company or factory?

A: We are factory.

Q. My components have already been developed on CAD. Can you use the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q. Can I test my idea/component before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models for design and functional evaluations.

Q. What type of plastic is best for my design/component?

A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!